7 AI Strategies for Retail Supply Chain Success in 2025

Unlocking the Power of Data:

By Chris Cassidy, Chief Revenue Officer, Seagull

By 2025, retailers who bridge the online-offline data divide will gain a decisive competitive edge, while those treating these channels in isolation risk missing crucial insights about the complete shopping journey.

Resilient and efficient retail supply chains rely on high-quality data. In an industry where accuracy, transparency, and responsiveness directly impact customer satisfaction and company profitability, achieving high data quality is crucial. Unfortunately, fragmented software platforms and inconsistent, incomplete data reports hinder the full potential of many retailers’ inventory management.

Artificial intelligence (AI) is transforming the industry by proactively addressing these challenges. With harmonized and orchestrated data capabilities, AI-powered retail systems help companies improve their operations and make better decisions.

Here is seven ways AI can improve data quality in the retail supply chain while integrating harmonized and orchestrated data to create a seamless ecosystem.

The Current State of Data Quality in Retail

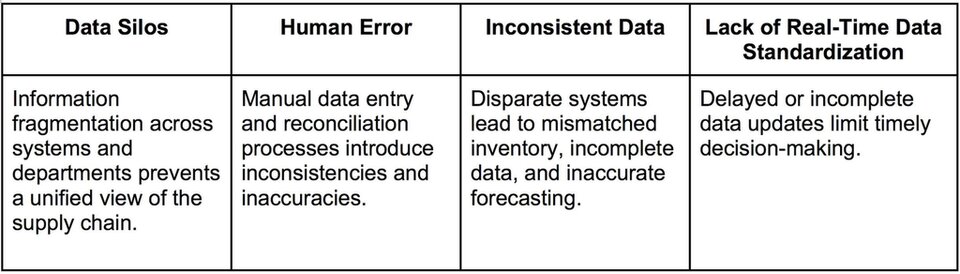

Retail supply chains are complex networks with many touchpoints, from sourcing raw materials to delivering finished products to consumers. Traditional tracking methods often fail to provide real-time visibility and accurate data. Why?

The consequences of these issues result in costly retail setbacks such as inaccurate forecasting, stockouts, compliance risks, and poor customer experiences.

The Need for Harmonized and Orchestrated Retail Data

In the context of supply chain traceability, "harmonized and orchestrated" refers to the seamless integration of standardized data elements with the strategic reorganization of processes, roles, and technologies.

Data Harmonization ensures that all platforms and stakeholders use uniform and comparable data, reducing errors and improving communication.

Data Orchestration aligns these harmonized data flows with efficient supply chain operations, improving visibility, reducing costs, and maximizing overall efficiency. Together, harmonized and orchestrated data create a robust, interconnected ecosystem that drives better decision-making and optimized performance across the supply chain.

With supply chain technology that harmonizes and orchestrates data, retailers harness a robust ecosystem that fosters collaboration, improves transparency, and drives operational excellence.

Using AI to Enhance Retail Data Quality

In retail, the global AI market size is expected to reach $85 billion by 2032 from its kickoff value of $7.14 billion in 2023. Productivity is a primary goal of using AI in retail as companies implement more automated solutions to improve efficiency and outperform competitors.

To implement AI effectively, retailers must ensure their data is reliable. High-quality data is essential for AI to move beyond generating historical reports to driving predictive, prescriptive, and automated actions. For example, accurately forecasting consumer demand relies on data that meets the highest standards of quality. Achieving harmonized and orchestrated data across the retail supply chain is crucial. Below is seven ways AI can enhance data quality.

- Automate Data Capture and Validation: AI-powered supply chain software streamlines data collection and validation processes. AI automatically captures and validates product information using barcode scanners and RFID technology.

Algorithms analyze product images to extract details such as product codes and expiration dates. AI can identify errors and inconsistencies to ensure harmonized data across platforms. - Achieve Real-Time Inventory Tracking and Visibility: Retail inventory systems that use AI achieve item-level tracking for detailed visibility into every level, location, and movement.

By analyzing historical data and trends, AI algorithms optimize inventory levels proactively through predictive analytics. Similarly, machine learning models enable accurate demand forecasting to prevent stockouts or overstock. - Increase Supply Chain Collaboration and Transparency: AI fosters collaboration by breaking down data silos between stakeholders. With the ability to integrate with blockchain technology, retailers can create immutable records of product provenance for authentic traceability.

Collaborative Planning, Forecasting, and Replenishment (CPFR) solutions facilitate communication between suppliers and retailers for better demand planning and inventory management. Ensure Intelligent Quality Control and Assurance: AI-harmonized and orchestrated systems ensure only the highest quality products reach customers. With intelligent quality inspection and control, it automatically detects product defects and quality issues during production—before getting shipped to customers.

Other features analyze equipment sensor data to spot potential issues so operators can proactively schedule preventive maintenance. This addresses equipment abnormalities before failures occur, minimizing downtime and improving operational efficiency.Leverage Advanced Analytics for Decision Making: Improve company decision-making with data-driven insights extracted from large volumes of data. Using machine learning and advanced algorithms, AI learns from historical data to identify anomalies or trends, presenting opportunities for improvement.

Prescriptive analytics can also provide recommendations for optimizing inventory levels and improving demand forecasting.Manage and Mitigate Risks: AI solutions help retailers build supply chain resilience with risk mitigation strategies. For example, risk assessment models analyze factors like supplier performance, natural disasters, and geopolitical events to identify vulnerabilities and develop risk mitigation options.

Personalize the Customer Experience: Retail software that uses AI directly impacts customer experiences. Personalized recommendations tailor product suggestions based on a customer’s purchasing history and preferences. It also improves order fulfillment to reduce lead times, leading to greater customer satisfaction.

Retail SaaS Solutions for Data Management - What Industry Experts Are Saying

It's no secret that AI is revolutionizing the retail space and industry leaders are leveraging this technology to much success.

According to a McKinsey report, early adopters of AI-supported supply chain management systems have decreased inventory costs by 20%. The same report also states that several major CPG companies have increased their revenue by up to 4% by using AI to ensure data quality throughout their supply chains.

These cost savings are also likely a byproduct of AI’s transformative impacts on demand planning and forecasting. Through advanced models, AI can help ensure companies properly anticipate consumer trends and demand across markets, leading to stronger purchasing, sourcing, and supply chain decision-making. In fact, by using AI, companies have enjoyed a 15% decrease in logistics costs and a 35% improvement in inventory levels. At scale, that’s millions of dollars of possibility.

Just as vital as cost savings and improved efficiencies, AI (when combined with IoT technologies) can provide something retailers need to get (and stay) ahead—enhanced visibility. A 2021 survey unearthed that fewer than 50% of companies knew the location of their tier 1 suppliers. For tier 2 suppliers and beyond—often the people who work with their tier 1 suppliers—that number plummeted to a minimal 2%.

A myriad of problems emerge from this lack of visibility, not the least of which is unforeseen supply chain disruptions, whether external forces like weather, epidemics, changes in trade routes, or altering customer demand, or internal ones like product recalls or supply shortages.

With AI and IoT technologies, companies can enhance traceability by better tracking products across their lifecycles. This insight can help companies make smarter purchasing and logistics decisions that positively affect their bottom line, consumer expectations, and regulatory demands.

Why Go AI?

AI adoption isn’t an option for retailers—it’s a necessity for survival in increasingly competitive and complex global markets.

A study by Lucidworks found that 92% of U.S. companies (96% in the tech and data science spaces) plan to increase their AI budgets.

After waves of crashing success, it’s easy to see why.

With AI, companies achieve centralized, real-time inventory visibility and gain data-backed insights to improve decision-making with:

- Cloud Integration: Retail SaaS platforms integrate with existing ERP, WMS, TMS, and other systems to ensure real-time data flow.

- Scalability: These AI solutions adapt to seasonal demand fluctuations or market changes, making them easily scalable.

- Centralized Visibility: Synchronized data from all locations provides an accurate, unified view of inventory levels across channels.

At a time when maintaining quality supply chain data is critical, retailers are turning to AI. With harmonized and orchestrated capabilities, companies overcome traditional challenges caused by fragmented systems, inconsistent data, and limited product visibility.

Chris has more than 25 years of executive leadership in various supply chain management roles. He has deep domain expertise and a stellar track record working with leading global enterprises on digital transformation and supply chain optimization. Chris is a recognized expert in supply chain management, logistics, and enterprise supply chain SaaS solutions, across both customer operations, strategy, sales and marketing. His current focus at Seagull is crafting and implementing the long-term strategic vision of the company to drive acceleration of the company’s growth and continue to lead the industry in customer satisfaction, global program delivery and product innovation for end-to-end visibility and traceability.

Before the merger of Mojix and Seagull Scientific in October 2024, Chris was President and CEO at Mojix. Previously, he held various supply chain leadership positions of increasing responsibility at Trax Technologies, Gartner, UPS, and GSK. He holds a BS in Industrial Engineering from Georgia Tech and an executive program certification in supply chain management at MIT.